No 6200 Stainless Steel Tube High

N06200/No6200 is a new type of NI-CR-MO alloy, which increases the chromium content based on C4 alloy and adds copper, g

Send your inquiryDESCRIPTION

Basic Info.

| Model NO. | 60*4 |

| Usage | Pipeline Transport, Boiler Pipe, Hydraulic/Automobile Pipe, Oil/Gas Drilling, Machinery Industry, Chemical Industry, Mining, Construction & Decoration |

| Section Shape | Round |

| Transport Package | Wooden Box |

| Specification | 600*600 |

| Trademark | dingyuxinda |

| Origin | China |

| HS Code | 7304112000 |

| Production Capacity | 50000ton/Year |

Product Description

N06200/No6200 is a new type of NI-CR-MO alloy, which increases the chromium content based on C4 alloy and adds copper, greatly improving the alloy's resistance to oxidation and reducing medium corrosion. It is currently the alloy with good resistance to sulfuric acid corrosion in this series, but its resistance to intergranular corrosion is not as good as C4.

N06200/No6200 resistance: In reducing media such as H2, SO4, HCL acid, and HF acid, its resistance to uniform corrosion is the same as others. It has improved the corrosion resistance of the alloy in oxidizing and reducing media, and is currently the alloy with good resistance to sulfuric acid corrosion in this series, but its resistance to intergranular corrosion is not as good as C4.

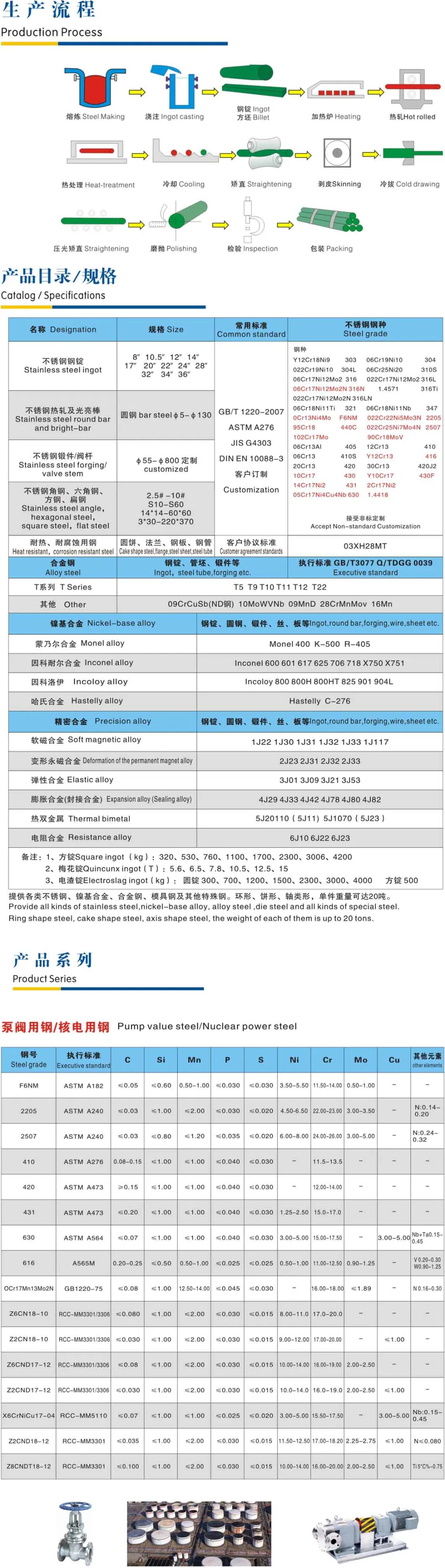

Company Profile

Wuxi Dingyu Xinda Special Steel Co., Ltd. has world-class metallurgical equipment, mature and stable technology, and safe and reliable process flow. The smelting of special functional superalloys adopts the VIM+VAR dual vacuum dual process and the VIM+PESR+VAR triple process for smelting production; Vacuum induction melting (VIM), vacuum consumable (VAR), atmosphere protected electroslag remelting (PESR) and conventional process IF+AOD+LF+VOD metallurgical equipment. Processing equipment such as heat treatment furnaces, peeling machines, rolling straightening machines, cold drawing machines, and coreless grinders; German Spike direct reading spectrometer, hardness machine, tensile machine, impact testing machine, automatic and manual ultrasonic non-destructive testing machine, eddy current non-destructive testing machine, corrosion testing machine,salt spray testing machine, German Leica metallographic microscope and other complete testing equipment. Since 2005, Dingyu.

F A Q

1. How can I know whether you are a reliable company?

We have been engaged in the steel industry for nearly 7 years and have a high reputation in China, We welcome you to inspect our company at any time.

2. Can you guarantee your products?

Yes, we guarantee your 100% satisfaction on all our products. Please feel free to feedback us immediately.

3. Do you provide samples?

Yes, we can provide most of the product samples. We will charge a little sample fee. But we will return the charge if you place an order. if you asked to use DHL, Blue Dart Express, FedEx, etc. to send samples, you can inform us in advance to prepare.

4. Can I visit your company?

Of course, If you want to order our products and visit our company, please contact us to make an appointment.

5. Can you make boxes according to my request ?

Yes,customization service is available,OEM business is appreciated.

When you place the orders,we arrange the production asap,When finish the orders, we will inform you and also we arrange the shipping in the same time.

6. How much is the freight?

It depends on the number and transport methods. When asked about the freight, we want you to let us know your detailed information , such as the product name and quantity and your favorite mode of transport, as well as your designated port or airport. We thank you for providing us the information to estimate the cost.

Related Products

-

![High Quality Rolled 99.9% 99.5% Copper Steel Wire Copper Strip Copper Tube Copper Pipe Copper Plate Foil Copper for Electric Wire Cable]()

High Quality Rolled 99.9% 99.5% Copper Steel Wire Copper Strip Copper Tube Copper Pipe Copper Plate Foil Copper for Electric Wire Cable

-

![Hot/Cold Rolled AISI SUS 201 304 316L 310S 409L 420 420j1 420j2 430 431 434 436L 439 No. 1/2b/Ba/No. 4/Brushed/8K Mirror Stainless Steel Coil]()

Hot/Cold Rolled AISI SUS 201 304 316L 310S 409L 420 420j1 420j2 430 431 434 436L 439 No. 1/2b/Ba/No. 4/Brushed/8K Mirror Stainless Steel Coil

-

![Tisco AISI SUS AISI 2b Ba Hl 8K Mirror Ss 430 410 420 SUS304 304L 202 321 316 316L 201 304 309S 310S Build Material Cold Rolled Metal Stainless Steel Roll Coil]()

Tisco AISI SUS AISI 2b Ba Hl 8K Mirror Ss 430 410 420 SUS304 304L 202 321 316 316L 201 304 309S 310S Build Material Cold Rolled Metal Stainless Steel Roll Coil

-

![Afp Az30 Az100 Aluzinc Galvalume Steel Coil for Building Material]()

Afp Az30 Az100 Aluzinc Galvalume Steel Coil for Building Material